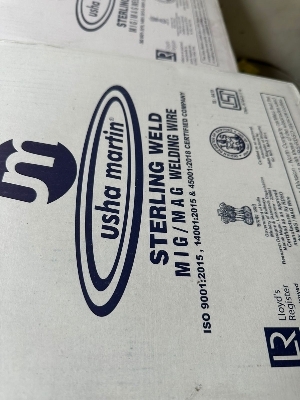

Stainless Steel MIG Welding Wire

280 INR/Kilograms

Product Details:

- Application Industrial MIG Welding

- Composition Fe, Cr, Ni, Mo (Typical Stainless Steel Alloy)

- Operating Voltage Standard MIG Voltage Settings

- Operating Temperature Up to 300C

- Usage Industrial

- Material Stainless Steel

- Diameter Different Sizes Available

- Click to View more

X

Stainless Steel MIG Welding Wire Price And Quantity

- 280 INR/Kilograms

- 1250 Kilograms

- Solid Wire

- 300 mm

- Excellent

- 15 kg

- AWS A5.9 ER 308/308L

- Plastic Spool

- 570 MPa min

- Bright and Smooth

Stainless Steel MIG Welding Wire Product Specifications

- Polished

- Fe, Cr, Ni, Mo (Typical Stainless Steel Alloy)

- Different Sizes Available

- Up to 300C

- Stainless Steel

- Nil

- Different Sizes Available

- Industrial

- Standard MIG Voltage Settings

- About 1400C

- Industrial MIG Welding

- Solid Wire

- 300 mm

- Excellent

- 15 kg

- AWS A5.9 ER 308/308L

- Plastic Spool

- 570 MPa min

- Bright and Smooth

Stainless Steel MIG Welding Wire Trade Information

- Cash Advance (CA)

- 5000 Kilograms Per Month

- 10 Days

- All India

Product Description

Stainless steel MIG welding wire is specifically designed for welding stainless steel materials using the MIG welding process. It's essential for applications where corrosion resistance and aesthetic appearance are crucial, such as in food processing equipment, chemical processing plants, and architectural structures.

Stainless steel MIG welding wires come in various grades, each tailored for specific applications and base materials. Some common grades include:

1. 304/304L: This grade is one of the most widely used stainless steel alloys for general-purpose welding applications. It offers good corrosion resistance and is suitable for welding a wide range of stainless steel components.

2. 308/308L: These grades are used for welding 18-8 stainless steel alloys, including types 301, 302, 304, and 308. They offer excellent corrosion resistance and are suitable for welding applications where post-weld annealing is not practical or desired.

3. 316/316L: These grades are used for welding molybdenum-bearing stainless steels, such as types 316 and 316L. They offer superior corrosion resistance, particularly in harsh environments containing chlorides or acids.

4. 309/309L: These grades are designed for welding dissimilar metals, such as stainless steel to carbon steel or low-alloy steel. They offer good resistance to high temperatures and thermal cycling.

5. 347: This grade is specifically designed for welding stabilized stainless steels, such as type 321. It contains columbium (niobium) to prevent intergranular corrosion after welding in high-temperature applications.

When selecting stainless steel MIG welding wire, it's crucial to match the wire composition with the base material to achieve optimal weld quality and performance. Factors such as wire diameter, shielding gas composition, welding parameters, and joint design should also be considered to ensure successful welding operations.

High Quality and Performance

This MIG welding wire features a bright and smooth surface finish, manufactured to the strict specifications of AWS A5.9 ER 308/308L. Its high tensile strength and excellent corrosion resistance make it ideal for a wide range of industrial applications, ensuring reliable and clean welds even in challenging environments.

Versatile Industrial Applications

Suitable for industrial MIG welding tasks, this stainless steel wire is optimal for fabricators, manufacturers, and maintenance professionals who require consistency and resilience. The absence of flux and high-quality composition ensure precise and contamination-free welds.

Packaging and Availability

Available in convenient 15 kg spools with a 300 mm diameter, this product suits automated and manual MIG welding setups. The durable plastic spool helps maintain wire integrity, while different diameter options accommodate various welding requirements. Sourced from trusted suppliers and traders in India, it is ready for immediate industrial use.

FAQ's of Stainless Steel MIG Welding Wire:

Q: How should I use the Stainless Steel MIG Welding Wire for optimal weld quality?

A: To achieve the best weld results, ensure your MIG welding machine is set to standard voltage and temperature settings, use the appropriate wire diameter for your application, and maintain a clean work surface. The wire's polished surface and solid composition help produce clean, strong welds with minimal spatter.Q: What benefits does this stainless steel MIG wire offer compared to other wire types?

A: This wire features exceptional corrosion resistance, a minimum tensile strength of 570 MPa, and a bright, smooth finish. It is highly durable and provides superior weld quality, especially in harsh or corrosive industrial environments, due to its robust stainless steel alloy composition.Q: When is this MIG welding wire recommended over other types?

A: This wire is ideal for applications where corrosion resistance, strength, and clean welds are essential, such as food processing equipment, chemical plants, and outdoor metal structures. Use it whenever your project demands high integrity and durability.Q: Where can I use this product?

A: The wire is suitable for a broad spectrum of industrial sectors, including fabrication shops, maintenance departments, and manufacturing lines. Its compliance with AWS A5.9 ER 308/308L ensures it performs reliably wherever high-quality stainless steel welds are required.Q: What is the welding process for this stainless steel solid wire?

A: Set your MIG welder to standard voltage and temperature for stainless steel, select the correct wire diameter, and feed the wire from the 15 kg plastic spool. No flux is required, allowing for a clean, efficient welding operation.Q: What sizes are available, and how do I choose the right one?

A: The wire comes in different diameters to suit specific welding tasks. Select a size that matches your application's thickness and required weld strength for optimal performance and efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS