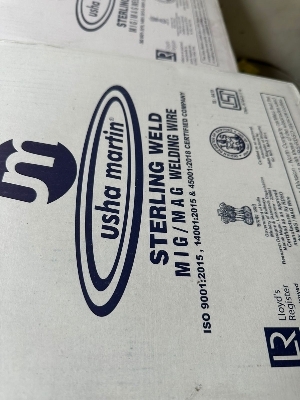

Copper MIG Welding Wire

102 INR/Kilograms

Product Details:

- Application Industrial MIG welding

- Operating Voltage Typically 15-32V (depends on application)

- Operating Temperature Optimal 150C to 250C

- Composition 99.9% Pure Copper

- Usage Industrial

- Material CO2

- Diameter Available in various diameters

- Click to View more

X

Copper MIG Welding Wire Price And Quantity

- 1500 Kilograms

- 102 INR/Kilograms

- Bright and smooth

- Standard industrial packaging

- >300 MPa

- Copper

- IS: 12725 or equivalent

- Customizable per spool

- Spool

- Suitable for automatic and semi-automatic MIG welding machines

Copper MIG Welding Wire Product Specifications

- Typically 15-32V (depends on application)

- Different Sizes Available

- Polished

- 99.9% Pure Copper

- Optimal 150C to 250C

- Available in various diameters

- Industrial

- No flux core; solid wire

- Approximately 1085C (Copper)

- CO2

- Industrial MIG welding

- Bright and smooth

- Standard industrial packaging

- >300 MPa

- Copper

- IS: 12725 or equivalent

- Customizable per spool

- Spool

- Suitable for automatic and semi-automatic MIG welding machines

Copper MIG Welding Wire Trade Information

- Cash Advance (CA)

- 5000 Kilograms Per Month

- 10 Days

- All India

Product Description

MIG (Metal Inert Gas) welding wire is a consumable electrode used in MIG welding processes. It is a type of welding where a continuous and consumable wire electrode is fed through a welding gun, which is also connected to a shielding gas supply. The wire electrode is melted and used as filler material to join two base materials together.

MIG welding wires come in various types, each suitable for different applications and materials:

1. Carbon Steel Wire: This is the most common type of MIG welding wire used for welding mild steel. It usually contains a small amount of manganese and silicon to improve its welding characteristics.

2. Stainless Steel Wire: Stainless steel MIG wires are used for welding stainless steel materials. They contain varying amounts of chromium and nickel to provide corrosion resistance and improve weldability.

3. Aluminum Wire: Aluminum MIG wires are used for welding aluminum and aluminum alloys. They may contain elements such as silicon and magnesium to improve weld strength and fluidity.

4. Flux-Cored Wire: Flux-cored MIG wires have a flux core inside the wire, which generates a shielding gas when melted. They are often used in outdoor welding or in situations where a shielding gas may be difficult to use.

When selecting MIG welding wire, factors such as the type of base material, thickness of the material, welding position, and desired weld characteristics should be considered to ensure proper weld quality and performance. Additionally, the diameter of the wire will affect the welding parameters and deposition rates.

Superior Conductivity for Precise Welding

Utilizing 99.9% pure copper, this MIG welding wire provides outstanding electrical conductivity and arc stability. The bright and polished finish reduces spatter, ensuring cleaner welds with efficient transfer rates. These attributes help improve weld quality and productivity in heavy-duty industrial settings.

Customizable Solutions to Suit Your Needs

Available in multiple diameters and spool weights, the copper MIG welding wire can be tailored to different project requirements. Standard industrial packaging ensures safe transport and storage. The product versatility accommodates a broad range of welding machines and applications.

FAQ's of Copper MIG Welding Wire:

Q: How is copper MIG welding wire installed on automatic or semi-automatic MIG welding machines?

A: Copper MIG welding wire is supplied on spools, making it easy to load into most automatic or semi-automatic MIG welding machines. Simply follow your machine's manual to thread the wire through the drive rollers and torch, ensuring correct tension for smooth feeding.Q: What are the benefits of using solid copper MIG welding wire?

A: Using solid copper MIG welding wire ensures excellent electrical conductivity, stable arcs, minimal spatter, and robust tensile strength exceeding 300 MPa. The wire's purity and polished finish result in cleaner, stronger welds, reducing post-weld cleaning and enhancing overall efficiency.Q: When should I choose copper MIG welding wire instead of other materials?

A: Copper MIG welding wire is recommended for industrial settings where superior conductivity, minimal oxidation, and clean welds are critical. It is especially useful when welding non-ferrous metals or in environments requiring consistent and high-quality weld joints.Q: Where can copper MIG welding wire be used effectively?

A: This welding wire is ideal for industrial MIG welding applications in manufacturing, automotive, electrical, and fabrication sectors. It is compatible with welding machines operating at 15-32V and within optimal operating temperatures of 150C to 250C.Q: What process does the copper MIG welding wire support?

A: The product is designed for the MIG welding process, which uses a shielding gas such as CO2 and a continuous solid wire electrode. Its fluxless composition delivers clean, reliable welds without the risk of flux contamination.Q: How do I select the right diameter and weight for my project?

A: Choose the diameter and spool weight based on your welding machine's specifications, material thickness, and desired weld strength. Suppliers offer customizable options, allowing you to select the ideal configuration for efficient, high-quality welds in your specific application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS