Mild Steel MIG Welding Wire

105 INR/Kilograms

Product Details:

- Application Automotive, Engineering, Fabrication, Construction

- Operating Voltage 14-36 V

- Composition Carbon, Manganese, Silicon, Trace Alloying Elements

- Operating Temperature Room Temperature to Arc Temp (up to 5000C, localised)

- Usage Industrial

- Material Stainless Steel

- Diameter 0.8 mm to 1.2 mm

- Click to View more

X

Mild Steel MIG Welding Wire Price And Quantity

- 1350 Kilograms

- 105 INR/Kilograms

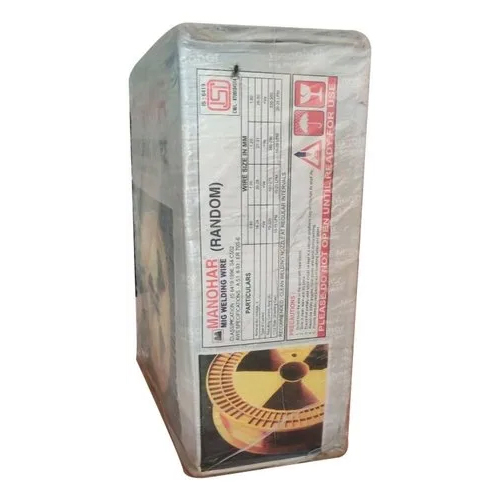

- Plastic spool, Vacuum packaging available

- Moderate (due to copper coating)

- EN ISO 14341

- 5 kg, 15 kg, 20 kg

- ER70S-6

- 0.01 mm

- 490 MPa

- Smooth, Bright

Mild Steel MIG Welding Wire Product Specifications

- 0.8 mm to 1.2 mm

- 14-36 V

- Automotive, Engineering, Fabrication, Construction

- No flux (solid wire)

- Industrial

- Stainless Steel

- Room Temperature to Arc Temp (up to 5000C, localised)

- Carbon, Manganese, Silicon, Trace Alloying Elements

- Approximately 1425C 1540C

- Different Sizes Available

- Polished

- Plastic spool, Vacuum packaging available

- Moderate (due to copper coating)

- EN ISO 14341

- 5 kg, 15 kg, 20 kg

- ER70S-6

- 0.01 mm

- 490 MPa

- Smooth, Bright

Mild Steel MIG Welding Wire Trade Information

- Cash Advance (CA)

- 5000 Kilograms Per Month

- 10 Days

- All India

Product Description

Mild Steel MIG Welding Wire is a type of welding wire used in the MIG welding process for joining mild steel workpieces. The wire is made of high-quality steel with a low carbon content, which makes it easy to work with and produces strong, durable welds. Mild Steel MIG Welding Wire is designed to be used with MIG welding machines that use a shielding gas to protect the weld from atmospheric contamination.

Superior Welding Performance

Designed for industrial use, our ER70S-6 MIG welding wire ensures high-quality and spatter-free welds. Its fine tolerance (0.01 mm) and solid composition-free from flux-allow for consistent melting and excellent bead appearance. Whether you need exacting automotive seams or structural fabrication, this wire delivers stable arc performance and dependable strength.

Versatile Sizes and Packaging

Our welding wire comes in multiple diameters (0.8 mm to 1.2 mm) and a range of spool weights (5 kg, 15 kg, 20 kg), making it suitable for diverse welding jobs, from small repairs to heavy-duty projects. The plastic spool and optional vacuum-packed packaging preserve wire quality, reduce corrosion, and help streamline shop operations.

Reliable Material and Corrosion Protection

Produced using high-grade mild steel with a polished copper coating, this MIG wire offers moderate corrosion resistance and retains a smooth surface for optimal wire feeding. Its carefully balanced composition ensures strong welds that meet EN ISO 14341 standards, providing peace of mind for both suppliers and end users.

FAQ's of Mild Steel MIG Welding Wire:

Q: How should I store Mild Steel ER70S-6 MIG Welding Wire to prevent corrosion?

A: To minimize corrosion risks, keep the wire in its original plastic spool and vacuum packaging until use. Store it in a dry, temperature-controlled area away from moisture and contaminants. The copper coating adds moderate corrosion resistance for enhanced protection during storage.Q: What are the main benefits of using ER70S-6 MIG welding wire in industrial applications?

A: ER70S-6 wire offers high tensile strength (490 MPa), stable arc characteristics, and consistent weld bead quality. Its moderate corrosion resistance from copper coating and smooth finish ensures efficient feeding, making it ideal for automotive, engineering, construction, and fabrication work.Q: When should I use vacuum packaging for this welding wire?

A: Vacuum packaging is recommended when long-term storage or shipping in humid environments is required. It safeguards the wire from oxidation and moisture, preserving its quality for optimal weld performance.Q: Where can this mild steel MIG wire be utilized?

A: This welding wire is suitable for a variety of settings, including automotive manufacturing, structural fabrication, engineering projects, and construction sites, wherever strong and precise mild steel welds are necessary.Q: What is the process for welding with this wire type, and do I need additional flux?

A: This is a solid wire with no flux core; it is used with a MIG welding setup, which requires shielding gas for operation. No additional flux is needed. Use it within an operating voltage of 14-36 V and a suitable shielding gas such as CO2 or Argon/CO2 mix.Q: How does the wire's composition affect weld quality?

A: The blend of carbon, manganese, and silicon, along with trace alloying elements, improves deoxidation and helps produce welds with reduced spatter and enhanced mechanical properties. This results in cleaner, more reliable joints.Q: What advantages come from the wire's precise tolerance and smooth, bright surface finish?

A: A wire tolerance of 0.01 mm and a polished, bright surface ensure consistent feeding through the welding torch, reducing downtime, and promoting stable, high-quality welds with minimal interruptions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS