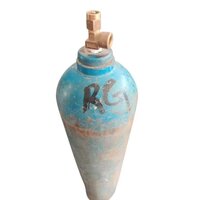

Liquid Nitrogen Gas Cylinder

700 INR/Unit

Product Details:

- Temperature -196C (Cryogenic Conditions)

- Capacity 120 Liters to 500 Liters

- Wall Thickness 6.2 mm to 7.2 mm

- Pressure 125-230 Bar (Working Pressure)

- Usage Industrial

- Material Stainless Steel

- Structure General Cylinder

- Click to View more

X

Liquid Nitrogen Gas Cylinder Price And Quantity

- 50 Unit

- 700 INR/Unit

- Optional (Available in Some Models)

- 476 mm to 778 mm

- Medical, Laboratory, Metal Industry, Research Facilities

- Cryogenic Valve with Safety Relief

- 250-360 Bar

- Vacuum Insulated Double Wall

- Liquid Nitrogen

- Polished or Powder Coated

Liquid Nitrogen Gas Cylinder Product Specifications

- Different Sizes Available

- High Performance Cryogenic Seals

- Stainless Steel

- 6.2 mm to 7.2 mm

- Industrial

- -196C (Cryogenic Conditions)

- Varies with Size

- General Cylinder

- 120 Liters to 500 Liters

- Different Sizes Available

- 125-230 Bar (Working Pressure)

- Optional (Available in Some Models)

- 476 mm to 778 mm

- Medical, Laboratory, Metal Industry, Research Facilities

- Cryogenic Valve with Safety Relief

- 250-360 Bar

- Vacuum Insulated Double Wall

- Liquid Nitrogen

- Polished or Powder Coated

Liquid Nitrogen Gas Cylinder Trade Information

- Cash Advance (CA)

- 5000 Unit Per Month

- 10 Days

- All India

Product Description

A nitrogen Gas Cylinder is a high-pressure storage container that holds nitrogen gas in its gaseous state. It is typically made of steel or aluminium and has a valve at the top for regulating the flow of gas. Nitrogen Gas Cylinder is commonly used in a variety of industrial applications such as welding, food processing, electronics manufacturing, and medical facilities. It is also used in the beverage industry for preserving the freshness and flavour of beer, wine, and other carbonated beverages.

Engineered for Cryogenic Performance

These liquid nitrogen cylinders combine robust stainless steel construction with advanced vacuum insulation, maintaining -196C under rigorous conditions. Their design, complete with high-performance seals and safety valves, maximizes thermal stability and user safety, making them well-suited for the demanding needs of medical, laboratory, and industrial sectors.

Versatile Sizes and Configurations

Available in a range of sizes with outer diameters from 476 mm up to 778 mm and capacities from 120 to 500 liters, there is a cylinder fit for every operational scale. Select models offer optional transport wheels, providing added mobility and convenience in dynamic environments.

Reliable and Safe Operation

Each cylinder undergoes stringent pressure testing between 250 to 360 bar, ensuring dependable storage and minimized risk. The polished or powder coated finish provides enhanced surface resilience, while the cryogenic safety relief valve delivers assured protection during use.

FAQ's of Liquid Nitrogen Gas Cylinder:

Q: How should a liquid nitrogen gas cylinder be installed and handled for optimal safety?

A: Ensure installation in a well-ventilated area away from heat sources. Always handle the cylinder by the provided grips or wheels (if available), and avoid dropping or tilting it. Use appropriate personal protective equipment when connecting or disconnecting the cylinder to prevent contact with extremely cold surfaces.Q: What are the main benefits of using vacuum-insulated double-wall cylinders for liquid nitrogen storage?

A: Vacuum-insulated double-wall construction minimizes heat transfer, effectively maintaining cryogenic temperatures (-196C) for prolonged periods. This design ensures reduced evaporation losses and greater safety during liquid nitrogen storage and transit.Q: When is it necessary to choose a cylinder with optional transport wheels?

A: Optional transport wheels are beneficial when frequent movement of the cylinder is required within medical, laboratory, or industrial facilities. They are especially useful in environments where portability is critical to workflow efficiency or safety.Q: Where can these liquid nitrogen cylinders be utilized?

A: These cylinders are ideal for use in a variety of settings, including medical facilities, research laboratories, metalworking industries, and other research-focused environments that require dependable cryogenic storage and transport.Q: What is the process for repressurizing or refilling the cylinder?

A: Refilling or repressurizing should be performed by trained professionals using standardized cryogenic transfer equipment. Always verify valve integrity and high-performance seals before and after refilling to prevent leaks or accidental exposure to cryogenic temperatures.Q: How does the cryogenic safety relief valve operate?

A: The cryogenic safety relief valve is designed to automatically release gas if internal pressure exceeds safe limits, thereby preventing cylinder rupture or other hazardous incidents. This feature ensures ongoing operational safety in all application areas.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS